In today's aggressive industrial landscape, efficiency is not only a purpose; it's the bedrock of survival and growth. organizations throughout sectors – from pharmaceuticals and electronics producing to aerospace and facts centers – continually seek ways to enhance procedures, lower squander, and greatly enhance profitability. nonetheless, a significant, typically invisible, drain on assets lurks while in the extremely air surrounding significant operations: airborne particulate contamination. These microscopic particles can wreak havoc, leading to solution defects, tools failure, abnormal Electricity consumption, and regulatory non-compliance. Fortunately, State-of-the-art technological know-how delivers a robust Remedy. Laser particle counters (LPCs) are rising as indispensable resources, going outside of straightforward air top quality checks to be strategic assets that actively lessen squander and travel considerable effectiveness gains. this post explores the multifaceted strategies LPCs empower businesses to obtain leaner, cleaner, and a lot more Price-successful functions by furnishing specific, genuine-time knowledge for clever final decision-earning.

Table of contents:

Precision Particle Monitoring & Filter program Optimization: the inspiration of Efficiency

Slashing Energy squander: Linking Clean Air with reduce electric power Bills

Optimizing Resource Utilization: reducing content Waste

Boosting Production effectiveness & Slashing Defect fees: Protecting solution high quality

Enhancing Environmental Command System (ECS) performance: Holistic program efficiency

Elevating company Environmental graphic & Compliance: Meeting benchmarks, lowering Risk

lessening servicing expenses & Extending gear Lifespan: Proactive treatment Pays Off

Precision Particle checking & Filter procedure Optimization: the muse of Efficiency

Air filtration techniques are the very first protection against particulate contamination, but devoid of appropriate monitoring, their general performance is commonly guesswork. Running filters much too very long wastes Strength, whilst replacing them as well early wastes means. lacking a drop in filter performance can cause highly-priced contamination. Laser particle counters get rid of the guesswork by offering actual-time knowledge on particle concentrations upstream and downstream of filters. LPCs accurately evaluate filtration efficiency (e.g., MERV scores in true problems), encouraging services administrators:

Validate Filter general performance: Confirm that installed filters are meeting their specified overall performance conditions in the real-globe environment, not just below perfect lab problems.

enhance Filter adjust Schedules: Move from time-primarily based filter substitute schedules in direction of condition-dependent servicing. LPC information reveals the precise instant a filter's effectiveness drops below satisfactory amounts, ensuring It really is changed just when necessary. This prevents untimely disposal of laser particle counter supplier continue to-useful filters and avoids the hazards affiliated with operating degraded filters.

recognize Leaks and Bypasses: Sudden spikes in downstream particle counts can right away show filter seal failures, improper set up, or bypasses in the ductwork, letting for rapid corrective motion in advance of important contamination happens.

avoid in excess of-filtration: in a few environments, specifying filters with excessively significant efficiency scores can result in substantial Electricity penalties because of enhanced pressure fall. LPC data will help decide the true standard of filtration needed to maintain the goal cleanliness degree, probably making it possible for for the use of considerably less restrictive, more energy-successful filters without compromising air high-quality.

This exact monitoring transforms filter administration from a reactive, plan-pushed job into a proactive, knowledge-pushed method, specifically minimizing squander connected with filter elements plus the labor associated with unnecessary improvements.

Slashing Power squander: Linking cleanse Air with Lower ability expenses

Strength intake is A serious operational cost, particularly for services with stringent air high quality necessities that count closely on HVAC and air filtration systems. managing these techniques at comprehensive capacity continually, despite actual need to have, is a big source of Vitality waste. Laser particle counters supply the intelligence required to work these methods much more effectively.

Demand-Controlled Filtration and air flow: LPCs keep an eye on particle degrees to enable desire-controlled units. When particle counts are low, the process cuts down enthusiast speeds or airflow, cutting Power use. If particles increase toward a set threshold, the system raises activity only as wanted, steering clear of constant highest Procedure.

Optimizing Air alter premiums (ACR): Cleanrooms generally rely upon higher ACRs to take care of cleanliness. LPC data can validate if latest ACRs are needed or can be safely and securely lessened though keeping ISO course or GMP quality, preserving Vitality by decreasing fan power.

cutting down Filter strain fall influence: Optimizing filter variety based on particle information lowers strain drops throughout the procedure. due to the fact supporter Power use is dependent upon conquering force drops, even compact reductions provide important Vitality cost savings.

Integration with making Automation programs (BAS): present day LPCs combine with BAS, earning particle count information a vital input for setting up Power methods. This allows HVAC systems to coordinate particulate load with occupancy, temperature, and humidity for greater performance.

By ensuring that Vitality is expended on air purification only when and the place It really is definitely required, LPCs add on to lowered operational expenditures along with a smaller environmental footprint.

Optimizing source Utilization: reducing Material squander

outside of Strength and filters, keeping clean up environments normally entails other consumables, including specialized cleaning brokers or protecting clothes. On top of that, the process of taking care of inventory for filtration parts carries its individual potential for squander. Laser particle counters aid enhance using these assets likewise.

qualified Cleaning endeavours: LPC information identifies parts or moments with higher particle degrees, making it possible for cleaning endeavours to concentration where essential most. This may lower cleansing frequency or intensity in continually clean spots, saving on provides and labor.

Data-pushed Consumable Management: LPC details can optimize replacement cycles for consumables like air purification media by correlating particle degrees with functionality. This stops throwing away partially utilized media or functioning with depleted ones.

lessening about-Procurement and Inventory Waste: actual-time information on filter performance assures exact inventory administration, avoiding over-stocking and lowering challenges like hurt, obsolescence, or expiry. This causes leaner inventory and less waste. Partnering having a reliable laser particle counter provider assures reliable access to checking gear without having overstocking.

Precision knowledge from LPCs permits a shift in direction of just-in-time resource allocation, reducing the squander associated with guesswork and around-provisioning.

Boosting Production Efficiency & Slashing Defect fees: guarding merchandise excellent

In many industries, specifically electronics, prescribed drugs, clinical units, and aerospace, particulate contamination is usually a immediate reason for solution defects, decreased yields, and dear rework or remembers. keeping a pristine output ecosystem is paramount.

Real-Time Contamination Alerts: LPCs alert operators immediately when particle counts exceed suitable concentrations. This allows brief action to pause generation, find the contamination resource (e.g., devices issues, staff mistake, content shedding), and repair it right before compromising a batch. This proactive method cuts scrap premiums and squander.

procedure Optimization: Monitoring particle stages for the duration of production ways can identify procedures that generate essentially the most contamination. This knowledge assists guideline system adjustments, devices changes, or localized extraction to attenuate particle technology, improving upon very first-pass yields.

Troubleshooting Yield troubles: When yields fall unexpectedly, LPC details features beneficial context. evaluating produce knowledge with historical particle developments will help immediately establish or rule out airborne contamination, rushing up troubleshooting and decreasing downtime.

cutting down Downtime: By preventing big contamination functions that have to have in depth cleansing, LPCs enable manage consistent manufacturing uptime and improve manufacturing efficiency.

By safeguarding the manufacturing environment, LPCs instantly translate into bigger product or service quality, lessened squander from defects, and improved Over-all gear success (OEE).

boosting Environmental Control procedure (ECS) performance: Holistic process effectiveness

Laser particle counters Do not just watch isolated factors; they supply insights in the general performance of the entire environmental control technique, like HVAC interactions, air managing units (AHUs), and In general airflow styles.

method Balancing Verification: LPCs can confirm that the ECS delivers good air high-quality to vital places. facts can expose imbalances, with a few locations above-ventilated and Other folks slipping small, encouraging change for more successful air distribution.

AHU overall performance checking: putting LPCs in advance of and after essential AHU elements (like cooling coils or humidifiers) can help assess their influence on particle degrees and detect concerns like coil fouling or h2o carry-above which will induce contamination.

lessening avoidable gear biking: By monitoring real particle load, units can keep away from pointless start/halt cycles and lessen don on enthusiasts, compressors, and dampers. This smarter Management lowers pressure and extends tools daily life.

This holistic check out enabled by LPCs assures all the environmental Regulate infrastructure operates proficiently, reducing energy use and mechanical tension through the board.

Elevating Corporate Environmental Image & Compliance: Meeting criteria, minimizing chance

In an period of escalating environmental consciousness and stricter polices, demonstrating accountable environmental stewardship is important. productive particle Handle is really a important element of this.

Demonstrating Regulatory Compliance: a lot of industries run below specific air excellent standards (e.g., ISO 14644, EU GMP Annex one). continual monitoring with calibrated LPCs supplies the documented proof necessary to show ongoing compliance, preventing most likely highly-priced fines, operational shutdowns, or harm to track record associated with non-compliance.

Supporting Environmental Reporting: Accurate info on air high-quality Management usefulness may be included into company sustainability studies, showcasing tangible endeavours to minimize environmental effects via successful Electricity use and minimized emissions affiliated with electrical power technology. When it comes to instrumentation, things like the trustworthiness of the satisfied a person laser particle counter offer chain or equivalent superior-conventional suppliers come to be pertinent for ensuring regular, reportable information.

lessening Environmental Impact: By optimizing energy usage and cutting down material waste (filters, scrapped merchandise), using LPCs right contributes to your lower carbon footprint and fewer landfill burden, improving the corporation's eco-friendly credentials.

making consumer and Stakeholder have faith in: Proactively handling and documenting air top quality demonstrates a determination to top quality and security, that may be a substantial Think about making have confidence in with buyers, regulators, and investors.

LPCs give the information spine for sturdy compliance systems and tangible environmental effectiveness improvements.

Reducing upkeep expenses & Extending gear Lifespan: Proactive treatment Pays Off

unpredicted gear failures are disruptive and expensive. Laser particle counters add to simpler predictive and preventive routine maintenance tactics, decreasing General servicing costs and maximizing the lifespan of crucial products.

Early Detection of apparatus Issues: adjustments in particle counts can sign mechanical difficulties in manufacturing machinery (e.g., bearing have on or insulation degradation). Investigating unconventional LPC readings may help establish and deal with problems before significant failures come about.

Optimizing servicing Schedules: LPC details don't just optimizes filter adjustments but in addition guards downstream tools (e.g., cooling coils, sensors) by reducing fouling and put on, extending cleaning or servicing intervals.

minimizing Emergency Repairs: Proactive, info-driven upkeep lowers the potential risk of catastrophic filter failures or contamination activities, lessening expensive unexpected emergency repairs and downtime.

knowledge for Root result in Evaluation: Historical particle rely facts aids servicing groups review failures, realize environmental disorders, and build prolonged-time period alternatives.

By enabling a change from reactive repairs to proactive, ailment-primarily based routine maintenance, LPCs reduced All round routine maintenance expenses and assist maximize the return on financial investment in crucial facility and generation tools.

The information is evident: overlooking specific airborne particle monitoring is really a costly error in The search for operational excellence. Laser particle counters are much more than measurement devices—they actively generate efficiency and decrease waste. From reducing Power prices and optimizing sources to strengthening output yields and ensuring compliance, the ROI of strong LPC checking is simple. This technology delivers actionable insights that assistance businesses lessen squander, Slash costs, enhance high quality, and greatly enhance environmental responsibility.To unlock these Advantages, partnering with an expert laser particle counter provider is key. corporations like Lasensor offer you Sophisticated devices, including the LPC-S110A, suitable for precision, reliability, and seamless integration into modern day industrial setups. Embracing this know-how isn’t nearly cleaner air—it’s about building a smarter, leaner, and much more rewarding potential.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Marla Sokoloff Then & Now!

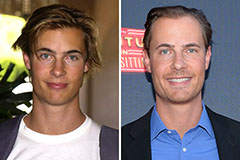

Marla Sokoloff Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!